Vapour Blasting Service based in Crawley, Sussex

Why It Works So Well

The combination of the water and glass bead slurry provides

a hydraulic cushioning effect to lessen the glass beads impact

on the metal’s surface. Working together, they provide a

peening/honing action that cleans the metal surface, resulting

in a finish that minimizes further staining and oxidation.

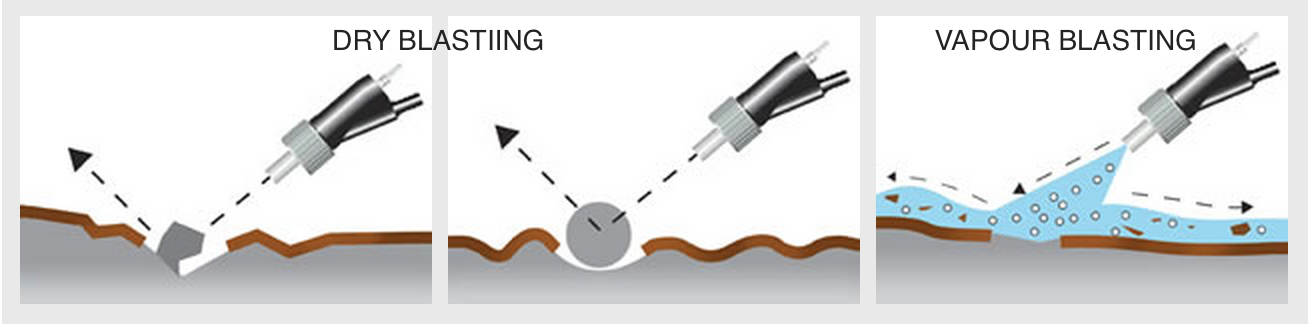

The aggressiveness of traditional dry shot and grit blasting can be seen in the first two diagrams which illustrate the severe deflection that happens when using the dry method.

The third diagram shows the much gentler, but just as effective, vapor blasting method. The deflection of the glass bead is greatly reduced due to the cushioning effect from the water; allowing a lapping process due to the angle of the media being much shallower. This gives an even satin/polished finish to the components being treated.

Industries and Applications Served

07487 452090

info@siclonemotodesign.co.uk